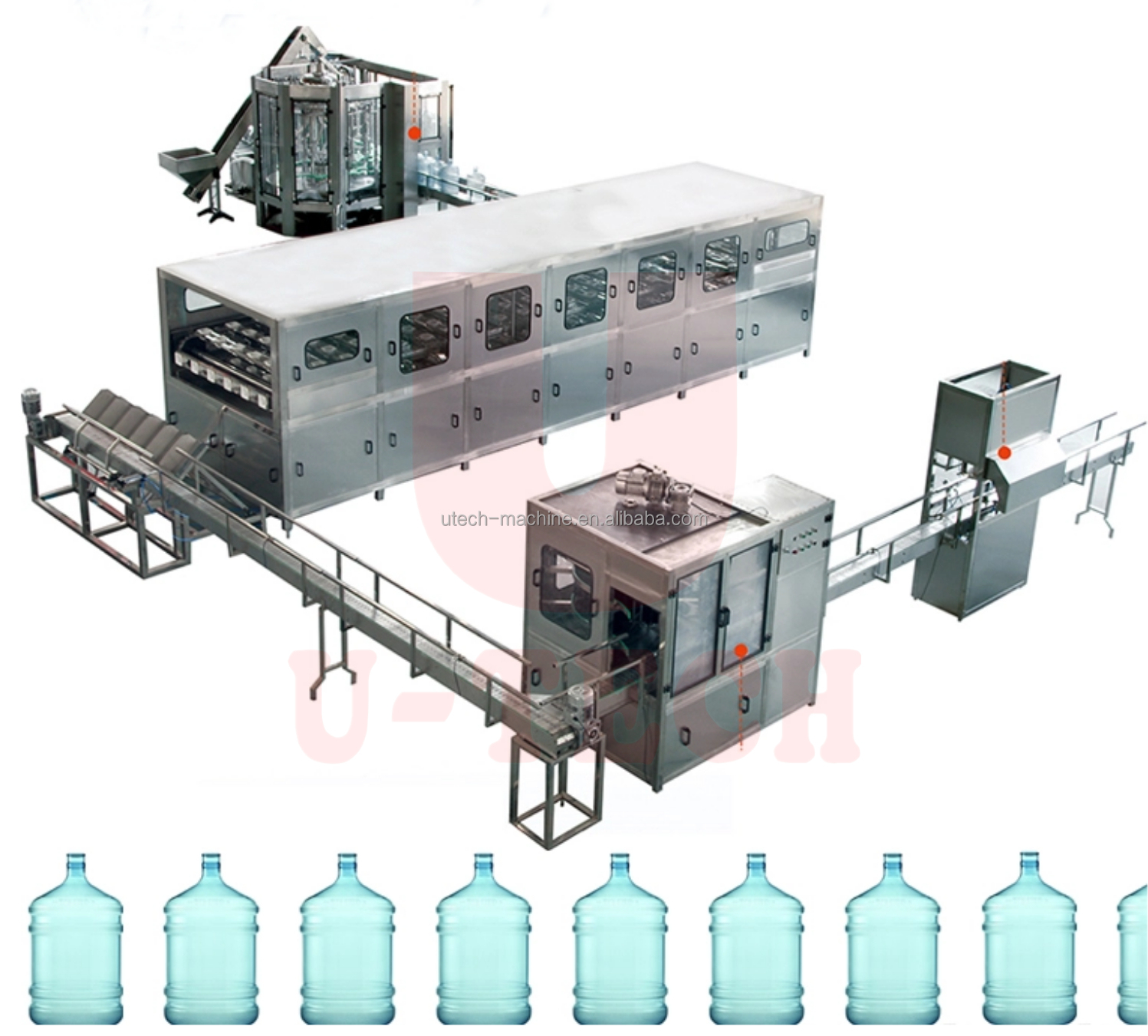

2021 U TECH 3-5 Gallon Drinking Water Bottle Washing And Cap Sealing Line / 20L Bottle Filling Capping Machine Price

Product Description

Product Description

Wholesale Pure Water Washing Filling Bottling Machine For 5 Gallon Barrel And Purification Plant

TXG series bottled water production line is mainly used in capacity between 3-5 gallon bottled water production of different models can provide 100-2000 bottles per hour of production capacity of the whole production line production process is: the empty bottle cover extracted by the conveyor belt steady input machine drawing machine is used to remove the lid, the lid can be recycled after cleaning and disinfection then carry on the omni-directional brush outside the bottle into the brush barrels machines after comprehensive external cleaning, the bottle into the washing, filling, screw cap, provide clean water by water treatment system for PET washing and fillingAfter the cap is finished, the bottled water enters the thermo-constrictor through the conveyor belt and the thermo-constrictor completes the packaging of the cap and shrink film inside the thermo-constrictor. The whole production process is controlled by PLC and the automatic operation control panel can monitor the working state of each part of the equipment directly, which is easy to operate.

Technical Parameters

Model | TXG-100 | TXG-150 | TXG-300 | TXG-450 | TXG-600 | ||||

Capacity(5 gallon) | 100BPH | 150BPH | 300BPH | 450BPH | 600BPH | ||||

Working position number | 3 | 5 | 7 | 9 | 11 | ||||

Filling heads | 1 | 1 | 2 | 3 | 4 | ||||

Capping heads | 1 | 1 | 1 | 1 | 1 | ||||

Suitable bottle | PET bottle,Plastic Bottle | ||||||||

Diameter of bottle | ∅265-273mm | ||||||||

Height of bottle | 150-360mm | ||||||||

Suitable cap | Plastic cap | ||||||||

Weight | 450Kg | 500Kg | 2500Kg | 3000Kg | 3500Kg | ||||

Main motor power | 1.4kw | 1.5kw | 6kw | 30kw | 32kw | ||||

Machine details

Pull out cover machine

Cap extractor, mainly in order to meet the needs of the majority of mineral water plant pure water plant manufacturers, the tedious empty barrel processing process into a simple automation.

External surface scour machine

The inside and outside nozzles used for washing the barrel are made of the unique technical equipment imported from American spray company.

Filling machine

The production line of pure water filling machine is the core equipment for the production line of 3-gallon and 5-gallon barrels of drinking water.

Screw cap machine

Capping machine is also called capping machine or capping machine, mainly used for plastic bottles and bottles.

Working process of pure water filling machine production line:

Microcomputer washing machine from bottle feeding - a disinfectant rinse clean water rinse - -push the fall in the evening of erect bottles of pure water filling - (cover) sets cover gland - finished product water is sent out, the whole operation process is controlled by PLC, accurate positioning automatically, using human less labor intensity and a full set of equipment adopt high strength stainless steel precision variant small welding argon arc welding of stainless steel plate grain is beautiful; The transmission part is stainless steel structure, which ensures the normal operation of the mechanism in various environments. Non-metallic parts are made of PP plastic and other non-toxic and high wear-resistant materials. Drive motor booster pump most choose domestic export series stainless steel products electrical components imported series or domestic brand series hardcover, so that the performance is more stable and reliable.

Main components brand configuration

S/N | Name | Brand | country |

1 | Main motor | ABB | Switzerland |

2 | inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- Relay | SCHNEIDER | France |

7 | Air-break Switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

Related Products

Semi Automatic 5 Gallon PET Bottle Blowing Machine In Chile

5 Gallon PC Bottle Extrusion Blow Molding Machine In Mongolia

PET preform Injection Molding Machine in Canada

Sleeve Labeling Machine

This machine adopts international advaced technology;cover the circle label on the pet bottle.And then hot shrinking to fix on the position which bottle body is designed.

This machine's structure is compact,and suitable for the production line of different direction and different height.

The machinery part adopts combination designing of modularization,and makes the machine reasonable.

The height adjustment adopts motor fluctuating;It is convenient to replace the material.The special cutter head designing,make the film-rolling cut more correct and reliable.

Steam Shrink Tunnel

In the case of diffenerent and irregular round bottles,square bottles and flat bottles and flat bottles etc,the new-style steam shrinking oven is easy to adjust and maintain.It has an even shrinking.The distribution of low-pressure steam drum and spouting way of steam are uniform and designed with seamless tube.The nozzle is divied to be adjustable three segments and the height,postion and steam output of every segment can be adjusted respectively so as to gain

the perfect shrinking effect.The whole machine is made of stainless steel with heat preservation,which not only saves energy,but also complies with the international safety standard.The stainless steel defrosting tray collects condense water.The whole machine adopts the water-proof design with the convenience of easy operation and low maintenance.

Electrical heating shrinking tunnel

With a unique design,the three segments of the hot air shrinking tunnel is independent and adjustable,which has improved efficiency thus delivering a saving of energy;After shrinkage,the outside of product has no water globules and it can be packed directly.

About U TECH

Certifications

FAQ

Q1:Do you have any reference project? >> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines? >>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years. Q3: Do you provide customized service? >> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid? >> A4:We will deliver the machines on time as the date we agreed both side. Q5:How can I install my machine when it arrives? >> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Product Categories : 3-5 gallon barrel water filling machine

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)