semi automatic 3-5 Gallon 20L 18.9L Drinking Water Bottle Washing machine

Product Description

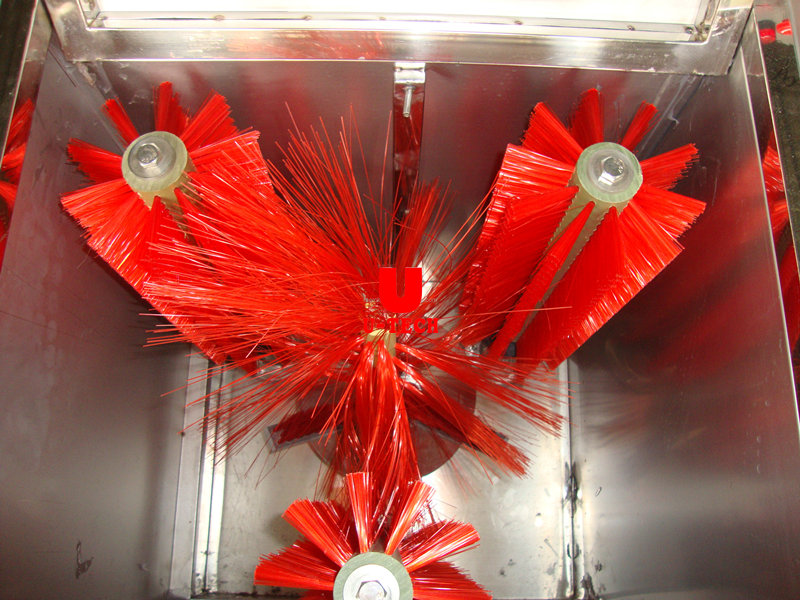

1. Brush, internal wash and external washing, three working conditions are completed in the same period, save time, energy and power.

2. The water supply mode, the user may reasonably choose circulating water supply, non-circulating water supply and multiple water supply mode according to need.

3. The cleaning effect is good, the machine is suitable for the inside and outside wall of the barrel body to be fully cleaned.

4. Simple operation, only one open door and closing operation can complete the whole process of scrubbing.

5. The pail extractor is suitable for 3 gallons and 5 gallons of drinking water recycling barrel lid and bucket separation. After disinfection, the cover is not worn or deformed. After disinfection, the cover can be reused, and the utilization of the lid is improved.

6. The equipment is reliable, easy to operate and easy to maintain, adopts 25 x 25mm stainless steel square tube welding machine frame, transmission mechanism, pneumatic reversing cover pull mechanism, electrical control, water spray parts, etc. It has the characteristics of smooth wear resistance and corrosion resistance.

Brush number | 6 (internal, external, upper and lower) | ||||||

Pull cap number | 1 | ||||||

Brush bucket number | 1 | ||||||

adapt to the bucket specification | 5 gallons (270 * 490 * 56mm Φ) | ||||||

Speed | 150-280 barrels per hour | ||||||

Voltage | 380V | ||||||

Power | 1.1kw | ||||||

Dimensions | 800*800*1200mm | ||||||

Weight | 100kg | ||||||

Decapping Machine

External brush washing Machine

Barrel are conveyed into the external brush washing machine to take all-round rinsing with hot alkali and pure water.barrel are conveyed into the external brush washing machine to take all-round rinsing with hot alkali and pure water.

Internal brush washing Machine

using three steps to make the barrel inside clean. hot alkali-----disinfectant liquid-----pure water

Filling Parts

1/Uploading and dropping barrels changed from 45 degree to translatory which is more stable.

2/Nozzle can insert into 10-15cm of the barrel in order to rinse little impurities down. Rinsing pump is separately controlled by different magnetic valves. Pump only work when there is barrel on that. It can avoid the mixture of different cleaning fluid.

Capping Parts

1/Liquid level difference is controlled in 1cm.

2/Machine is equipped with Cap Sterilization system, which is 1.2m. The system make products more clean and safe by using sterilization and finished water.

Advantages

1.The 5 Gallon Filling Machineis composed of barrel washer, barrel filling machine and barrel sealer into one unit.

2. Especially for filling drinking water of 3 and 5 gallons. It is an idea filling line to produce mineral water, distilled water and purified water.

3. The whole line is made of superior stainless steel, anticorrosive and easy to clean.

4. Only two operators are needed for a line, which is wholly automatic barreled

5. Full-auto or semi-auto barrel de-capper, full-auto leakage inspection, full-auto barrel outside brusher, full-auto barrel loading machine, steam shrinking film machine and coding system can be choose depends on what customer's need.

Bottle Blowing Machine

Sleeve labeling machine

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.

Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink, oil, alcohol, plant protein drink, etc.), barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

Our Customers

Q1:Are you a trading company or a manufactory?

A1:We are a manufactory,can give u best service .

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years

Q3:When can I get my machine after I paid?

A3:We will deliver the machines on time as the date we agreed both side.

Q4:How can I install my machine when it arrives?

A4:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Q5:How about the spare parts?

A5:After we deal down all the things , we will offer you a spare parts list for your reference.

Product Categories : 3-5 gallon barrel water filling machine