Complicated Auto 3-5 Parts Cap lining machine cap wadding machine cap liner inserting putting machine by quality factory

Product Description

Product Introduction

Description

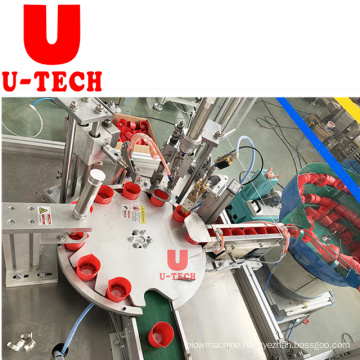

Automatic cap lining machine , which can cut the foil roll into liner and insert the liner into cap at the same time, with the speed up to 120 pieces/min. The body is provided with a turntable, the periphery of the turntable is provided with an equidistant groove matching with the bottle cap, and a bottle cap finishing and conveying device is arranged on one side of the body, and a bottle cap conveying device is arranged on the machine body, and the punch of the blanking device is installed at the pad in position One side of the blanking device of the gasket is provided with a discharging and rolling frame directly above the groove.The structure of the utility model can directly stuff the gasket into the bottle cap after blanking, which has a high degree of automation, greatly reduces the labor intensity of workers, and improves the production efficiency.

Main features:

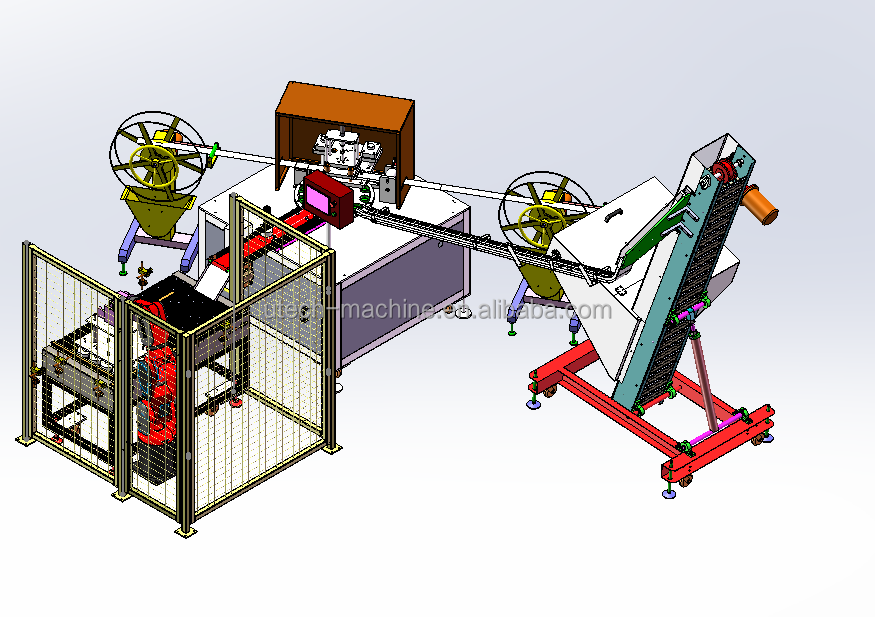

1. including one set host equipment, one set pulp liner Locate and inserting equipment,one set pulp roll sending machine,one set wasted pulp roll colloecting machine, one cap elevator.

2. one set round cap liner model;

3. PLC system, touch screen operation system.

4. automatic cap arranger,automatic Rejection system for improperly caps , which upside down.

5. the turntable locating, cutting and inserting the pulp liner into cap more precisely.

6. the foil roll diameter for foil sending machine: inner diameter is 76mm, outside diameter is no less than 500mm.

7. the length of pulp roll can be adjustable. So it can make sure the inserting job more precisely.

8. high quality and performance. It can work 24 hours per day and no stopping.

9. with counting function and output pre-setting function10. with the detect function for liner missing and reject the no liner cap (this function is base on the cap colour different from pulp liner colour)

11. system stop and alarm when caps are in short supply

12.safety running: automatically alarm and stop when breakdown occur

13. The work speed is 120 caps per min.

14. Electric Power source :220V,50-60HZ, Single power supply;(also, can be design according to customer requirement)

15. use UL PLC, touch screen, Switching Power Supplier, button.

Main features:

1. including one set host equipment, one set pulp liner Locate and inserting equipment,one set pulp roll sending machine,one set wasted pulp roll colloecting machine, one cap elevator.

2. one set round cap liner model;

3. PLC system, touch screen operation system.

4. automatic cap arranger,automatic Rejection system for improperly caps , which upside down.

5. the turntable locating, cutting and inserting the pulp liner into cap more precisely.

6. the foil roll diameter for foil sending machine: inner diameter is 76mm, outside diameter is no less than 500mm.

7. the length of pulp roll can be adjustable. So it can make sure the inserting job more precisely.

8. high quality and performance. It can work 24 hours per day and no stopping.

9. with counting function and output pre-setting function10. with the detect function for liner missing and reject the no liner cap (this function is base on the cap colour different from pulp liner colour)

11. system stop and alarm when caps are in short supply

12.safety running: automatically alarm and stop when breakdown occur

13. The work speed is 120 caps per min.

14. Electric Power source :220V,50-60HZ, Single power supply;(also, can be design according to customer requirement)

15. use UL PLC, touch screen, Switching Power Supplier, button.

Technical Parameters

model | UT-GD01 |

Speed | Max 120 caps/min |

Electricity power | 380V, 50HZ |

power | 2000W |

Air compression | 30L/min, ≥0.4Mp |

host equipment size | 1100mm*900mm*1400mm |

Cap elevator and cap feeding device | 1700mm*750mm*1200mm |

Foil sending device | 500mm*500mm*750mm |

Waster soil sending device | 500mm*500mm*650mm |

conveyor | 1200mm*100mm*200mm |

Machine weight | 1100Kg |

Details Images

Related Products

About U TECH

Package and Delivery

Certifications

FAQ

Q1:Do you have any reference project? >> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines? >>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years. Q3: Do you provide customized service? >> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid? >> A4:We will deliver the machines on time as the date we agreed both side. Q5:How can I install my machine when it arrives? >> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Product Categories : cap machine > cap machine

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)