Automatic beverage juice soda beer liquid Capping filling machines production line PET bottle sparkling water Making MACHINE

Product Description

Product Introduction

Automatic bottle water/ juice/ carbonated drink beverage filling packing machine production line

Carbonated drink filling equipment adopts bottle neck holding transmission technology to realize fully automatic bottle rinsing,pulp filling ,carbonated filling and cap screwing. It employs single cavity plunger type of fixing filling volume technique. It is equipped with CO2 accuracy pressure control, so that the liquid level is always stable. The application of alarm devices for bottle jam, bottle shortage, bottle damage, cap shortage, over loading etc. in several places ensure the quality of its production. The machine obtains advantages of high reliability, high efficiency, high grade of automation and easy operation etc.

Machine Specification

Soda drink / Sparkling beverage / Carbonated drink filling machines

Bottle Type: Bottles , Cans

Bottle Volume: 100-2500ml

Production Speed: 1000-32000bph

Bottle Size:

Height 170-320

Diameter 20-100

Bottle Volume: 100-2500ml

Production Speed: 1000-32000bph

Bottle Size:

Height 170-320

Diameter 20-100

Model | DCGF16-12-6 | DCGF18-18-6 | DCGF24-24-6 | DCGF32-32-10 | |||

Production Capacity(B/H) | 2000-4000 | 4000-6000 | 6000-8000 | 8000-12000 | |||

Filling Precision | <=5mm(Liquid Level) | ||||||

Filling Pressure(MPa) | <0.4 | ||||||

Polyester Bottle Satandard(mm) | φ40-φ80 | Bottle Diameter: φ50-φ100 Height:150-320 | |||||

Suitable Cap Shape | Plastic Screw Cap | ||||||

Water Pressure of Washing Bottle(MPa) | 0.18-0.25 | ||||||

Water Consumption for Washing Bottle(kg/h) | 1300 | 2000 | 2500 | 3000 | |||

Spraying Position | 5 | 5 | 6 | 12 | |||

Dripping Bottle Position | 2.5 | 3.0 | 3.5 | 7 | |||

Gas Consumption (m³/min) | 0.3 | 0.4 | 0.4 | 0.5 | |||

Total Power(kw) | 5.03 | 5.03 | 6.57 | 8.07 | |||

Total Weight(kg) | 2000 | 3000 | 4000 | 5000 | |||

Main Features of soft drink filling machine

1. Using the wind sent access and move wheel in the bottle directly connected technology; canceled screw and conveyor chains, this enable the change the bottle-shaped become easier.

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

7. Soft Drink Bottling Plant

2. Bottles transmission adopt clip bottleneck technology, bottle-shaped transform not need to adjust the equipment level, only change related the curved plate, wheel and nylon parts is enough.

3. The specially designed stainless steel bottle washing machine clip is solid and durable, no touch with the screw location of bottle mouth to avoid secondary pollution.

4. High-speed large gravity flow valve filling valve, filling fast, filling accurate and no liquid lose.

5. Spiraling decline when output bottle, transform bottle shape no need to adjust the height of conveyor chains.

6. Host adopt advanced PLC automatic control technology, the key electrical components from famous company such as Japan\'s Mitsubishi, France Schneider, OMRON.

7. Soft Drink Bottling Plant

Working Principles of soft drink filling machines

The carbonated beverage filling machine is self-designed and manufactured according to the principle of equal pressure filling,which can fill liquid into the bottle washing machine sent by the bottle washing machine.

The filling valve adopts an equal pressure mechanical valve, the filling is fast and sensitive, and the filling level has high accuracy. The centering guide adopts guide rod centering and unique bottle mouth clamping technology, which can ensure the accurate sealing between the bottle mouth and the filling valve and reduce the leakage of materials from the bottle mouth. The main transmission adopts gear transmission, that is, open combined transmission, which has high efficiency, low noise, long service life, convenient maintenance and sufficient lubrication. The frequency converter is used to control the speed of the main motor of the machine, and the machine adopts stepless frequency conversion control. The bottle guide system has a simple structure

and can be quickly and easily replaced according to the bottle type.

The whole machine adopts a bottleneck structure for transportation. The whole machine is automatically controlled by PLC, and online display of bottle jams, missing bottle caps and other faults. The material in the filling tank is automatically controlled,and the liquid level sensor detects the height of the liquid level to ensure a stable liquid level and reliable filling.

The filling valve adopts an equal pressure mechanical valve, the filling is fast and sensitive, and the filling level has high accuracy. The centering guide adopts guide rod centering and unique bottle mouth clamping technology, which can ensure the accurate sealing between the bottle mouth and the filling valve and reduce the leakage of materials from the bottle mouth. The main transmission adopts gear transmission, that is, open combined transmission, which has high efficiency, low noise, long service life, convenient maintenance and sufficient lubrication. The frequency converter is used to control the speed of the main motor of the machine, and the machine adopts stepless frequency conversion control. The bottle guide system has a simple structure

and can be quickly and easily replaced according to the bottle type.

The whole machine adopts a bottleneck structure for transportation. The whole machine is automatically controlled by PLC, and online display of bottle jams, missing bottle caps and other faults. The material in the filling tank is automatically controlled,and the liquid level sensor detects the height of the liquid level to ensure a stable liquid level and reliable filling.

Details Images

01-Air Conveyor.

1.Air conveyor is fixed on the floor, with fan installed on the top.

2.Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

-3.Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

4.All are made of stainless steel SUS 304 /316.

5.Rack made by high quality carbon steel welded.

2.Air filter is positioned at every entrance of air fan, to prevent dust blown into bottles.

-3.Bottles are held on the neck in the conveyor and transported into filling machine by blowing power.

4.All are made of stainless steel SUS 304 /316.

5.Rack made by high quality carbon steel welded.

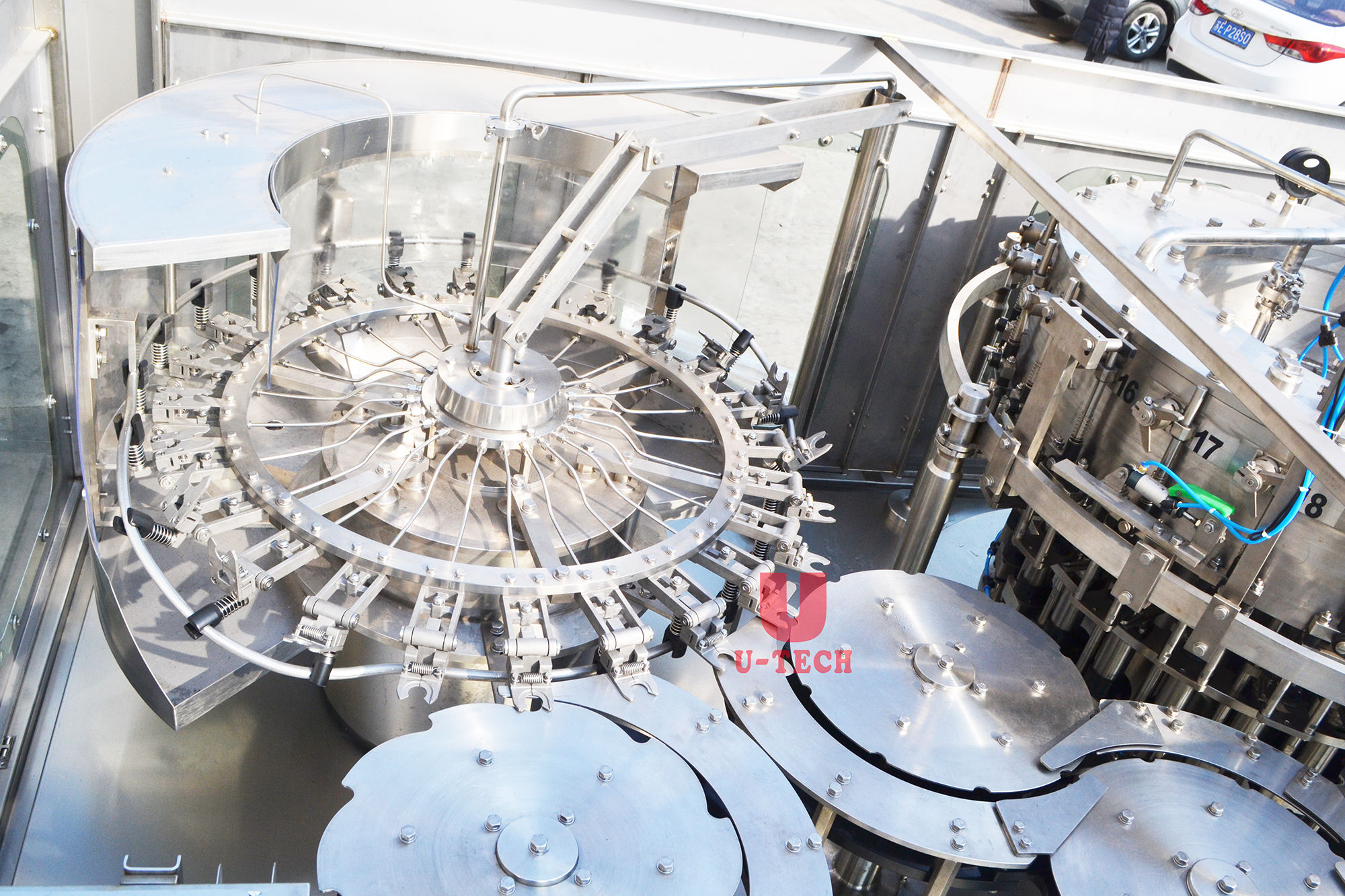

02-Washing Parts

1. Enhanced food safety: Stainless steel 304/316L for all components in contact with your beverage

2. Optimum uptime: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4. Hygiene improvement through volume control and contactless filling

2. Optimum uptime: 30 % reduction in changeover and maintenance downtime

3. Sustainable solution: Reduced filler enclosure and servomotors reduce resource consumption

4. Hygiene improvement through volume control and contactless filling

03-Filling Parts

1. 304/316 Stainless steel high precision filling nozzle

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushing

2. Filling volume adjustable in fine rank, same liquid level after filling

3. All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

4. 304/316 stainless steel filling pump

5. Efficient spray nozzle rinse thoroughly and save water for flushing

04-Capping Parts

1. Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during capping

2. All 304/316 stainless steel construction

3. No bottle no capping

4. Automatic stop when lack of bottle

5. Capping effect is stable and reliable ,Defective rate ≤0.2%

3. No bottle no capping

4. Automatic stop when lack of bottle

5. Capping effect is stable and reliable ,Defective rate ≤0.2%

05-Flat Conveyor

1.Energy saving. High efficient. Adapt to customer factory layout

2.Special lubrication system, keep products clean, health, safety

3.Extended service life

4.Electric eyes design keep whole line running safety and quickly

5.Overload protection mechanism to effectively ensure the safety of the machine

2.Special lubrication system, keep products clean, health, safety

3.Extended service life

4.Electric eyes design keep whole line running safety and quickly

5.Overload protection mechanism to effectively ensure the safety of the machine

Production Flow Chart

Different Liquid Filling Machine

Automatic 3 in 1 carbonated soft drink filling machine plant In Uzbekistan

Suitable : Carbonated Drink,etc.

Bottle Material :PET/Metal

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker Label / Shrink Label

Bottle Type : Round / Square / Unique

Cap : Screw cap

Label : Sticker Label / Shrink Label

Can filling line In Mexico

Suitable : Carbonated Drink,etc.

Bottle Material :Metal

Bottle Type : Round

Cap : Sealing cap

Label : Printing Label / Shrink Label

Bottle Type : Round

Cap : Sealing cap

Label : Printing Label / Shrink Label

Soda water filling line In Nigeria

Suitable : Soda Water,etc.

Bottle Material :PET/Glass

Bottle Type : Round

Cap : Screw Aluminum cap

Label : Sticker Label / Shrink Label

Bottle Type : Round

Cap : Screw Aluminum cap

Label : Sticker Label / Shrink Label

Beverage Mixer

The mixer is mainly suitable for mixing process of all kinds of carbonated drinks.

Auto Bottle Blowing Machine

<1>New Auto Preform Unscrambler System<2>Perfect heating system design decrease power consumption.

<3>Special oven design helps power-saving and easy maintain.

<3>Special oven design helps power-saving and easy maintain.

The most effective system of water technology,which is the use of ultra-thin film reverse osmosis membrane by water pressure

Bottle Warming Machine

This machine can increase the temperature of cold filling carbonated drinks to 36℃-40℃

Double Station Shrink Sleeve labeling machine

It adopts double driving structure which is a new and advanced driving device for the thermal shrink sleeve machine

About U TECH

Zhangjiagang U Tech Machine Co., Ltd. is a manufacturer of filling machine and packing with well-equipped testing facilities and strong technical force. With a wide range, good quality, reasonable prices and stylish designs, our products are extensively used in beverage and other packing equipment.Our products include: liquid filling machines (water, fruit juice/tea, carbonated drink,oil, alcohol, plant protein drink, etc.),barreled filling line (3-5 gallon) water treatment machines, labeling & packing machines, semi-automatic /full automatic PET bottle blowing machines, and injection molding machines, extrusion blow molding machines (PP/PE/PVC/PETG/PC...) and accessories for automation: leak tester machines, bottle bag packing machines, conveyor belts.

Certifications

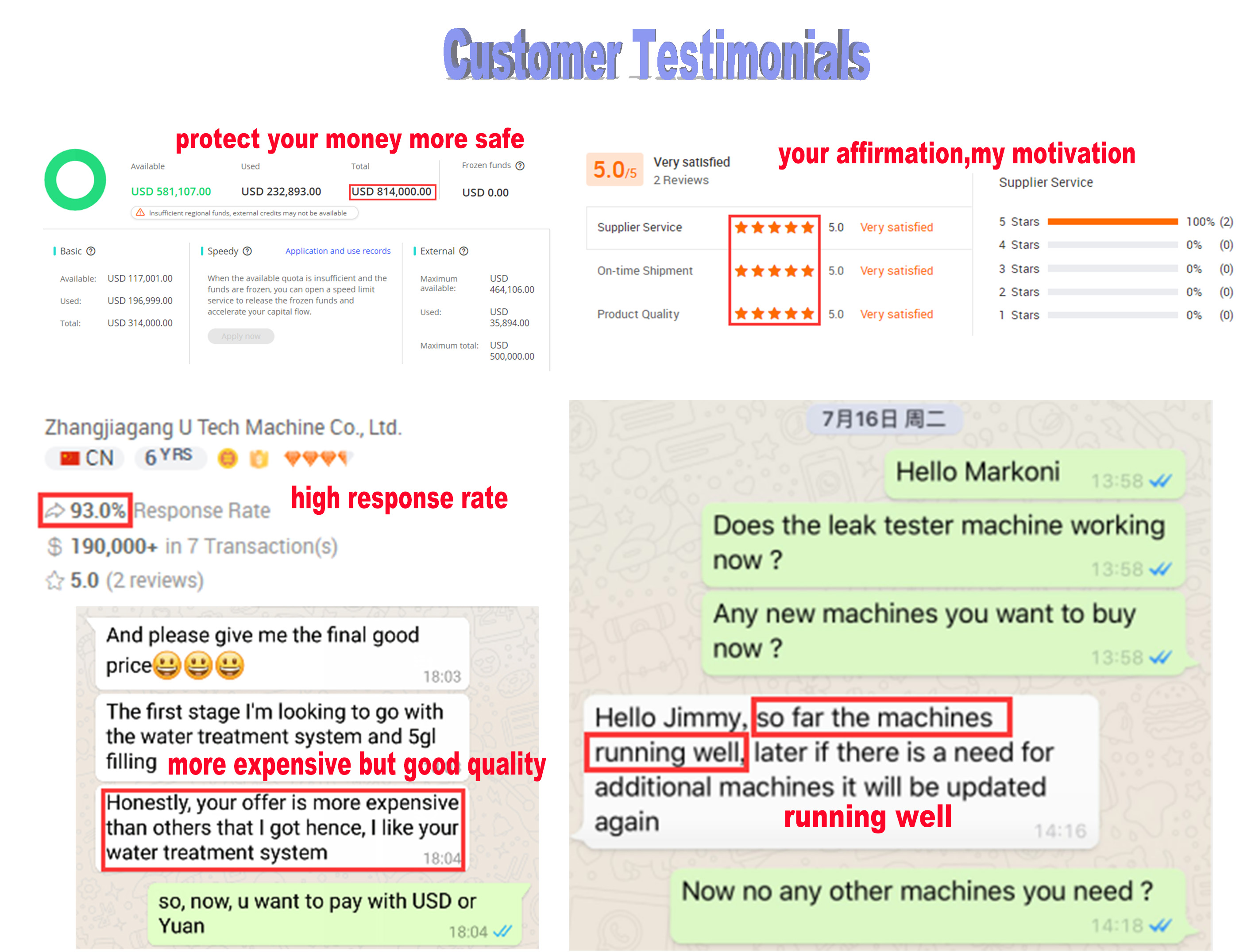

FAQ

Q1:Do you have any reference project? >> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines? >>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years. Q3: Do you provide customized service? >> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid? >> A4:We will deliver the machines on time as the date we agreed both side. Q5:How can I install my machine when it arrives? >> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Product Categories : carbonated beverage filling machine

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)