2021 U TECH factory direct sale Extrusion Blow Molding Machine for Making Plastic PE PVC LDPE PP Bulb ocean Sea Ball Toy

Product Description

Product Introduction

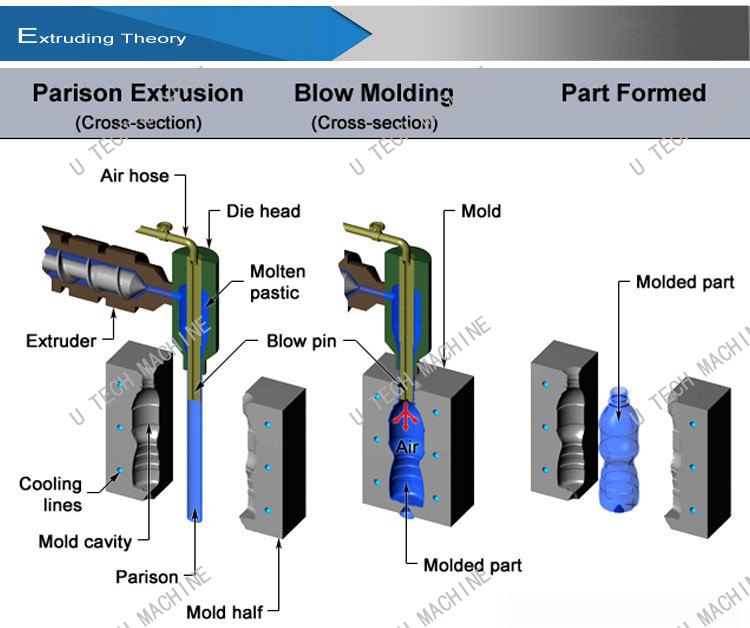

The BST series full automatic Extrusion Blow Molding Machine is specialized for the hdpe Jerry Can and drum volume.The machine with high efficient plasticizing screw and heating zones. The machine equips with LCD touch screen and Mitsubishi PLC system, very easy and high level operation. The blowing pin is designed to be at bottom with multi function.

Technical Parameters

Specifications | Units | BST50 Series | BST65 Series |

Material | PE,PP,PV,PVC,PA | PE,PP,PV,PVC,PA | |

Max Container capacity | L | 2 | 5 |

Number of die head | set | 1,2,3,4 | 1,2,3,4 |

Output (dry cycle) | Pc/hr | 1500 | 1000 |

Machine dimension(LxWxH) | M | 2.8x1.7x2.5 | 3.1x1.8x2.6 |

Total weight | ton | 4 | 4.5 |

Clamping system | |||

Clamping force | KN | 56 | 68 |

Platen opening stroke | mm | 150-500 | 150-500 |

Platen size | mm | 320x360 | 320x360 |

Move mould stroke | mm | 420 | 420 |

Min mould thickness | mm | 205 | 205 |

Hydraulic system and Penumatic system | |||

Motoe power of oil pump | KW | 7.5/11 | 11/15 |

Max pressure | Mpa | 10 | 12 |

Air pressure | Mpa | 0.6 | 0.7 |

Air consumption | M3/min | 0.4 | 0.6 |

Average engergy consumption | KW | 12 | 17 |

Extruder system | |||

Screw diamater | mm | 50 | 65 |

Screw L/D ratio | L/D | 24 | 24 |

Plasticing capacity | Kg/hr | 40 | 70 |

Number of heating zone | zone | 3 | 3 |

Extruder heating power | KW | 10.8 | 13.8 |

Extruder driving power | KW | 11 | 15 |

Die-head | |||

Number of heating zone | Zone | 2 | 3 |

Power of die heating | KW | 4.2 | 5.7 |

Max die pin heating | mm | 75 | 135 |

Center distance of double die | mm | 130 | 160 |

Center distance of tri-die | mm | 90 | 110 |

Center distance of tetra-dia | mm | 75 | 85 |

Machine details

Features:

1) Electrical control system: The machine works under the PLC control(made by the Mitsubishi Co. of Japan) via a man-and-machine interface(displayed in Chinese version or in English version).The machine is equipped with a modularized temperature controller and operated through a touch-type coloure screen.All the production data can be set up,modified,searched and monitored and the machine trouble diagnosis can be completed both on the touch-type screen.The electric elements work on the non-contact working principle,thus being durable in service life.

2) Hydraulic system:The machine works under the proportional pressure control. The machine is equipped with hydraulic valves and hydraulic pumps imported from world-famous companies,thus assuring consistent and reliable working performance.

3) Plasticizing system:The high performance screw used on the machine assures thorough and homogeneous plasticization and mixing of plastics.

4) Speed regulation system:Frequency-converter-controlled speed regulator + speed change gearbox with hardened alloy steel gears.Speed regulation can be completed smoothly with less noise generated.Therefore the machine is durable in service life.

5) Mould opening,closing & moving system:A big 3-point central beam mechanism for opening & closing the mould halves and locking the mould assures balanced distribution of locking force and is free of any deformation after long-time operation.The mould is horizontally moved on linear spherical ball guideways at high traveling accuracy and rapid speed and with less resistance.

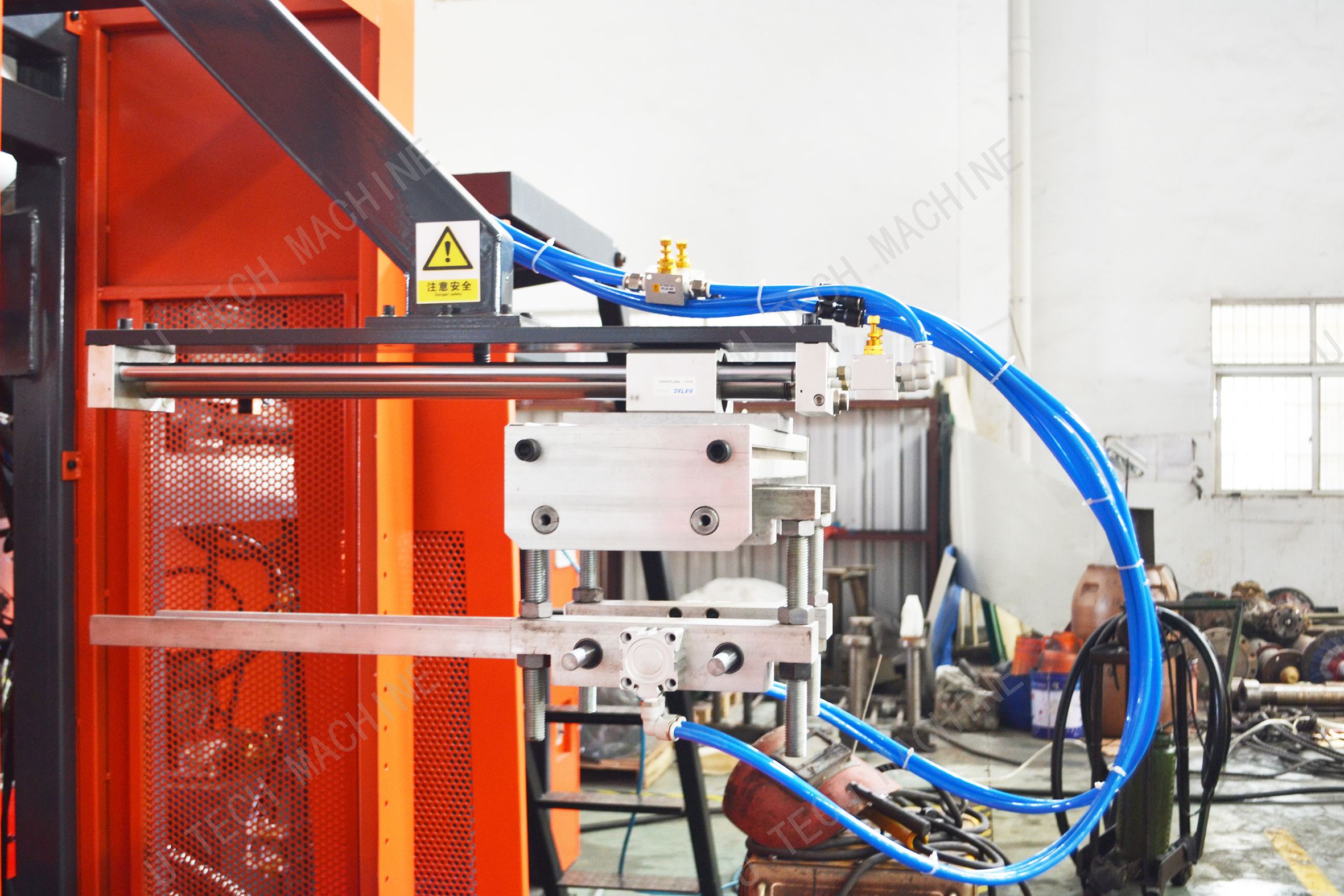

6) Air-bolowing needle bracket:The air-blowing needle bracket is of solid L-square design.The sturdy bracket assures smoothness of the product cut.

Bottle Samples

Related Products

About U TECH

Certifications

FAQ

Q1:Do you have any reference project? >> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines? >>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years. Q3: Do you provide customized service? >> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid? >> A4:We will deliver the machines on time as the date we agreed both side. Q5:How can I install my machine when it arrives? >> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Product Categories : extrusion blow machine and auxiliary > extrusion blow machine and auxiliary

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)