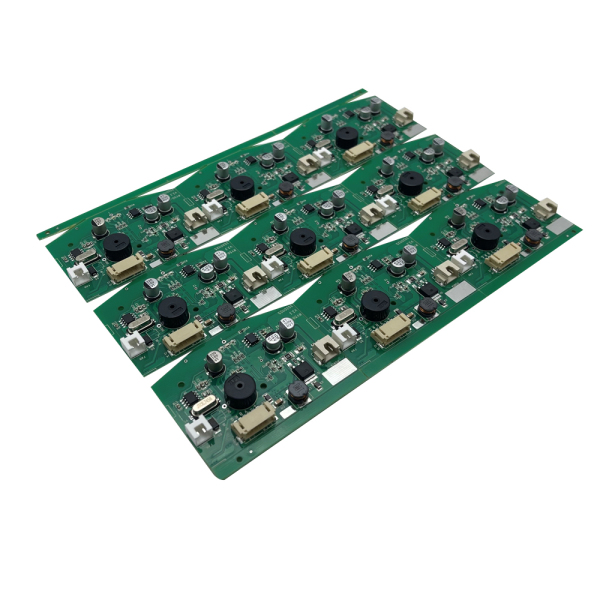

Industrial Control PCBA Circuit Board

Basic Info

Model No.: modular industrial control pcb

Product Description

What PCB means?

PCB (printed circuit board) is a printed circuit board, abbreviated as printed circuit board, which is one of the important parts of the electronics industry. Almost every kind of electronic equipment, from electronic watches to computers, communication electronic equipment, military weapon systems, as long as there are electronic components such as originality electronics IC, in order to make the electrical interconnection between the various electronic components, printed boards must be used . The printed circuit board is composed of an insulating bottom plate, a connecting wire, and a pad for assembly and welding of Electronic Components, and has the dual functions of a conductive circuit and an insulating bottom plate.

It can replace complex wiring and realize the electrical connection between the Electronic Components in the circuit. It not only simplifies the Surface-Mount (SMT) &BGA Assembly, Wave Solder for PCBA work, reduces the wiring workload in the traditional way, and greatly reduces the labor of workers. Labor intensity; and reduce the volume of the whole machine, reduce product costs, and improve the quality and reliability of electronic equipment. The printed circuit board has good product consistency, and it can adopt standardized design, which is conducive to the realization of mechanization and automation in the production process.

At the same time, the entire printed circuit board that has been assembled and debugged can be used as an independent spare part to facilitate the interchange and maintenance of the entire product. At present, printed circuit boards have been extremely widely used in the manufacturing of electronic products.

The earliest printed circuit boards used paper-based copper-clad printed boards. Since the emergence of semiconductor transistors in the 1950s, the demand for printed boards has risen sharply. In particular, the rapid development and wide application of integrated circuits have made the volume of electronic equipment smaller and smaller, and the density and difficulty of circuit wiring have become greater and greater, which requires continuous updating of printed boards.

At present, the variety of printed boards has developed from single-sided boards to double-sided boards, multilayer boards and Rigid-Flex Boards; the structure and quality of the Microwave radio frequency board has also developed to ultra-high density, miniaturization and high reliability; new designs Methods, design supplies, board-making materials, and board-making techniques continue to emerge. In recent years, various computer-aided design (CAD) printed circuit board application software has been popularized and promoted in the industry. Among specialized printed board manufacturers, mechanized and automated production has completely replaced manual operations.

PCB has the following characteristics:

The reason why PCB can be used more and more widely is because it has many unique advantages, which are roughly as follows:

1. High density (HDI PCB)

Over the years, the high density of printed boards has been able to develop correspondingly with the improvement of integrated circuit integration and the advancement of mounting technology.

2. High reliability

Through a series of inspections, tests and aging tests and other technical means, the PCB can be guaranteed to work reliably for a long time (usually 20 years).

3. Designability

The requirements for various properties of PCB (electrical, physical, chemical, mechanical, etc.) can be achieved through design standardization and standardization. In this way, the design time is short and the efficiency is high.

4. Manufacturability

PCB adopts modern management, which can realize standardization, scale (quantity) and automatic production, so as to ensure the consistency of product quality.

5. Testability

A relatively complete test method and test standard have been established. Various test equipment and instruments can be used to detect and appraise the eligibility and service life of PCB products.

6. Assemblability

PCB products are not only convenient for standardized assembly of various components, but also for automated and large-scale mass production. In addition, by assembling the PCB and various other components as a whole, larger parts and systems can be formed to the complete machine.

7. Maintainability

Since PCB products and various components are assembled in a standardized design and large-scale production, these components are also standardized. Therefore, once the system fails, it can be replaced quickly, conveniently and flexibly, and the system can be quickly restored to work.

PCB has other advantages, such as miniaturization and light weight of the system, and high-speed signal transmission.

The color of common PCB boards is brown or green. This is the color of solder mask and the insulating layer for PCB board protection, which can protect the copper wire and prevent the circuit from being affected by the wrong soldering of components. A thin screen printing surface is usually printed on the solder mask. Symbols and text are usually printed on the screen printing surface, which can indicate the information and location of electronic components in a certain position. So the screen printing surface is also called the icon surface by us.

However, as the functions of electronic devices become more and more complex, naturally more and more parts are needed, and the electronic components and circuits on the PCB board are naturally more and more dense. The PCB area that cannot be increased has become the main factor restricting the development of PCB. So the improvement of PCB is imminent.

Product Categories : High Frequency Board > Industrial Control PCB