Small desktop silicone benchtop syringe PET HDPE Plastic Inject injection blow molding machine Machinery For Bottle Preform Cap

Product Description

Product Introduction

Preforms for cosmetic products

Bearing in mind the characteristics of the cosmetics industry, we have developed the special high performance color mixing screw for PET colour preforms with a L/D ratio of 24:1. For PET materials such as iridescent and opalescent powders, it effectively improves the quality of color mixing and stability of products and ensures the surface color uniformity after blow molding.

Water and oil preforms

A special PET high-speed screw for water and oil preforms designed according to the characteristics of

ordinary water bottle and oil bottle industries provides a L/D ratio of 24:1 and achieves a high-speed and high-quality plasticizing under low shear conditions. It increases the plasticizing efficiency by nearly 100% compared with standard injection molding machines and boosts the original PET capacity by more than 30%.

ordinary water bottle and oil bottle industries provides a L/D ratio of 24:1 and achieves a high-speed and high-quality plasticizing under low shear conditions. It increases the plasticizing efficiency by nearly 100% compared with standard injection molding machines and boosts the original PET capacity by more than 30%.

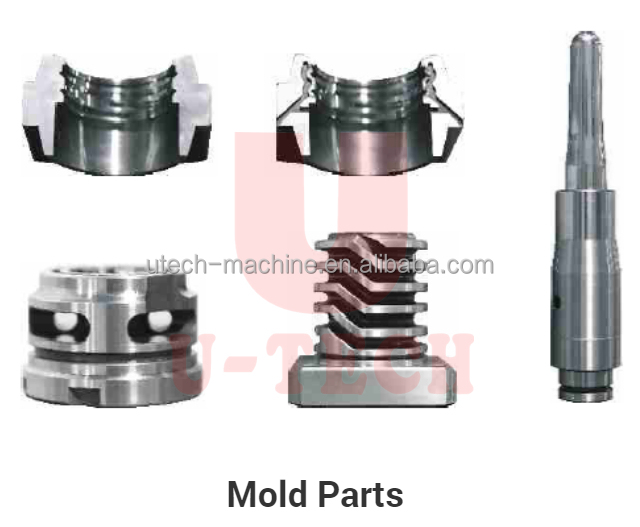

Machine details

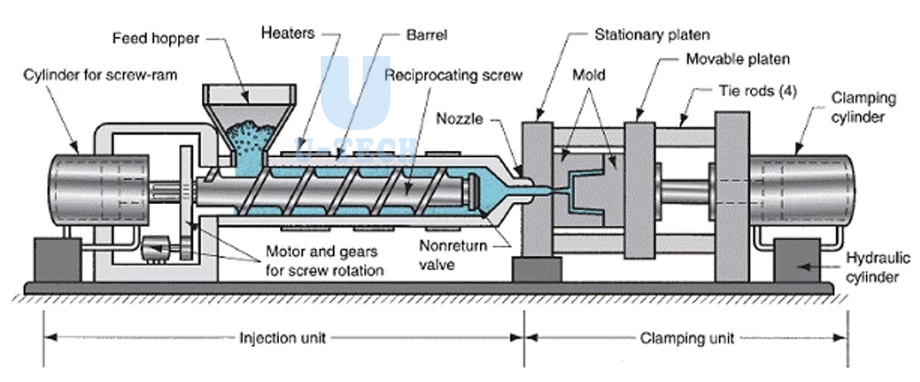

Injection Unit

Injection speed ,pressure and holding in five levels PID barrel temperature control with auto-tuning and ;1℃ accuracy High torque and high precision hydraulic motor with 99-step speed control for optimal melt environment

Cold-prevention starting device with low temperature alarm to prevent damage of the injection unit caused by low temperature Decompression device to prevent nozzle from drooling

Cold-prevention starting device with low temperature alarm to prevent damage of the injection unit caused by low temperature Decompression device to prevent nozzle from drooling

Customized Shot Weight

Depending on the needs of current and future products and the suitable types of products and molds for each model, the machine can be customized with different injection weight options to meet requirements on product weight.

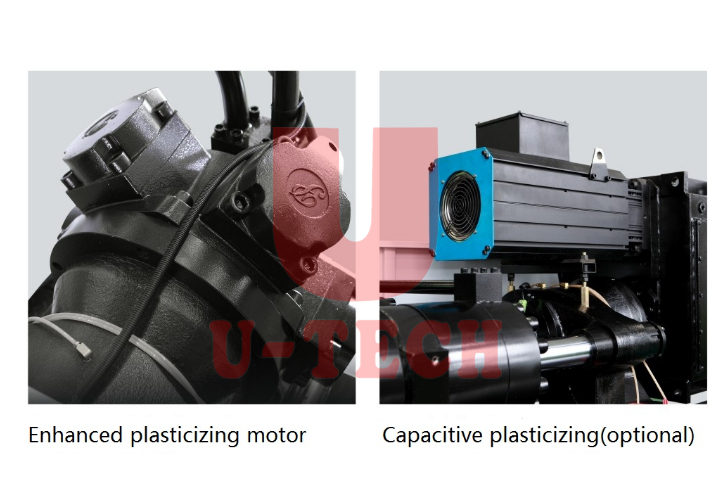

High-performance Plasticizing System

Custom made enlarged plasticizing motor with enhanced motor displacement to ensure the service life of motor and stability of products. The synchronous plasticizing (electrical plasticizing) is available among other options. Compared to the standard PET injection molding machines, the production efficiency can be increased by more than 10%.

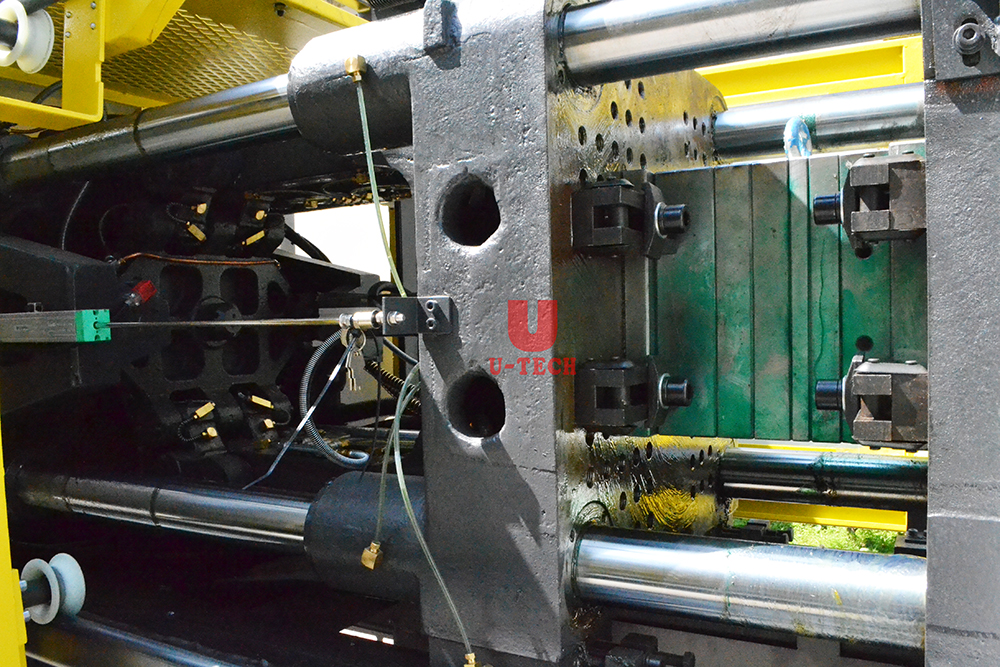

Clamping Unit

Tie bars are made of imported Japanese high tensile steel with specially-hardened, chrome-plated surface; Diameter is lengthened to minimize wear-out and maximize durability. Robust in-house manufactured ductile iron-casted platens guarantee durability and

minimize platen deformation. Multi-stage clamping speed and pressure control Automatic setting for high pressure clamping position Central electric fixed-dosage lubrication system Ejector speed and pressure adjustable and does not need to full retract during vibration which shortens cycle time

minimize platen deformation. Multi-stage clamping speed and pressure control Automatic setting for high pressure clamping position Central electric fixed-dosage lubrication system Ejector speed and pressure adjustable and does not need to full retract during vibration which shortens cycle time

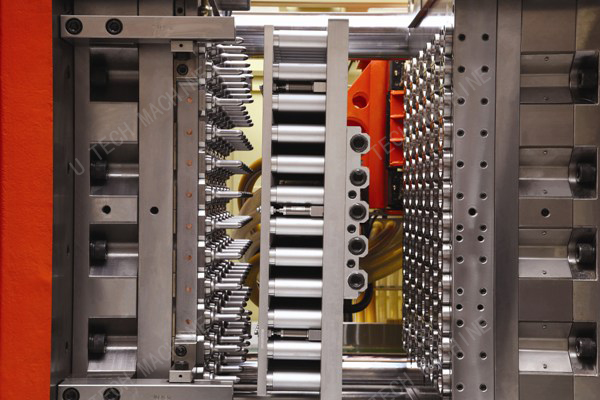

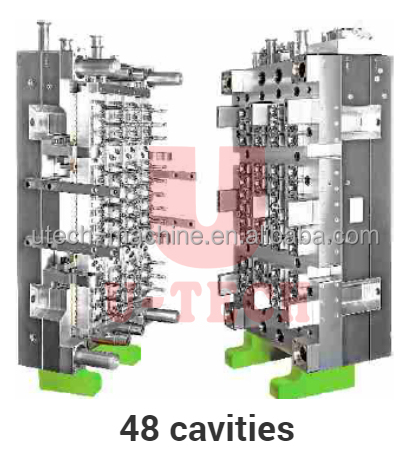

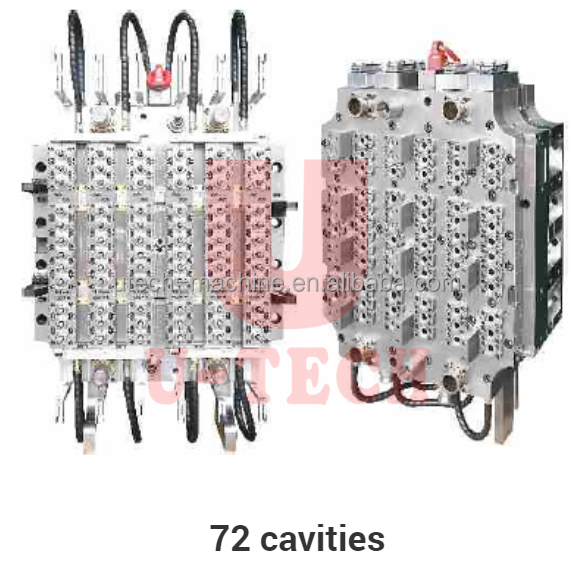

User Friendly Design

Standard robot mounting holes to facilitate an easy and fast installation. Mold needle valve control function is available as options to effective reduce the internal stress of product and improve the production yield.

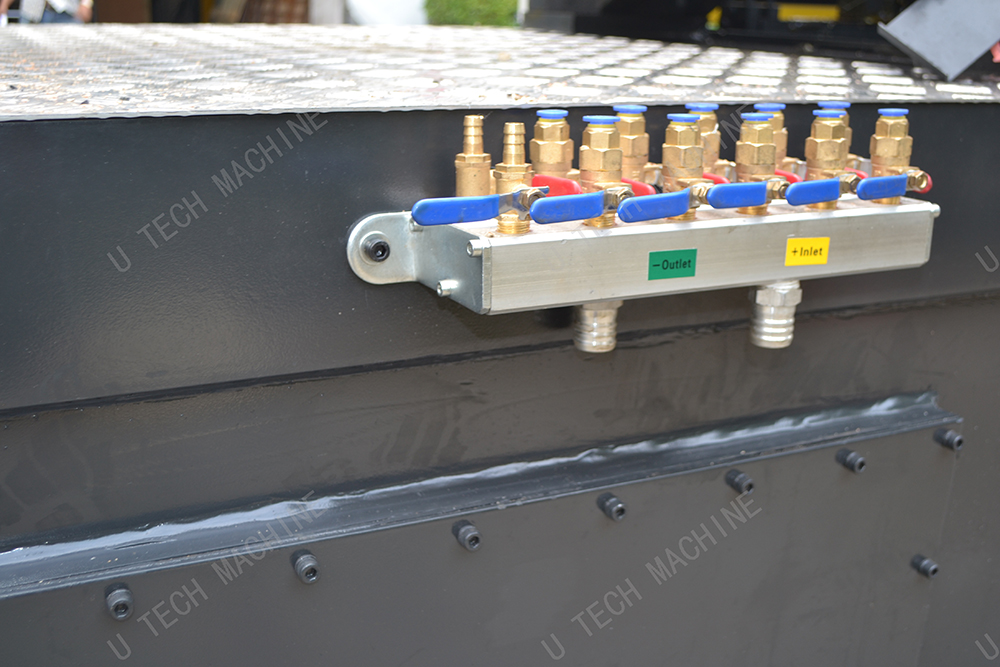

Optimized Cooling Water Transmitting Device

Enlarged cooling water transmitting device to ensure the transparency of PET products.

Enlarged Motor and Pump

By increasing the power of motor and pump, achieve higher productivity with a speed 20% faster than conventional machines.

Optimized Cooling Effect

Larger cooler and oil tank capacity effectively lower the oil temperature and improve the cooling effect.

Technical Parameters

DESCRIPTION | UNIT | DATA | |

Injection unit | Shot volume | cm3 | 3377.2 |

Shot weight (PS) | g | 3951.3 | |

oz | 139.4 | ||

Screw diameter | mm | 100 | |

Injection pressure | Mpa | 103.9 | |

Screw L:D ratio | 24:1 | ||

Max. injection speed | mm/s | 100 | |

Plasticizing Capacity (PET) | g/s | 233 | |

Screw stroke | mm | 430 | |

Screw speed(stepless) | r/min | 0-104 | |

Clamping unit | Clamping force | kN | 4000 |

Opening stroke | mm | 700 | |

Space between bars | mm*mm | 760x710 | |

Max. Daylight | mm | 1430 | |

Mold thickness(Min.Max) | mm | 240-730 | |

Ejector stroke | mm | 210 | |

Ejector number | 13 | ||

Ejector force | kN | 182 | |

Power unit | Hydraulic system pressure | Mpa | 17.5 |

Pump Motor | kw | 70 | |

Heating capacity | kw | 45.6 | |

Number of temp control zones | 7 | ||

Oil tank capacity | L | 720 | |

Machine dimensions(LxWxH) | m*m*m | 8.89x2.12x2.03 | |

Machine weight | kg | 15300 |

Cleanliness

Equipped with a high-performance oil fitler,hydraulic oil is repeatedly filtered and cleaned during normal machine operation.It reaches NAS8(USA)standard,which means the oil can be cleaner then new oil.This greatlyenhances the useable life of hydraulic system. Noise is also minimized during operation

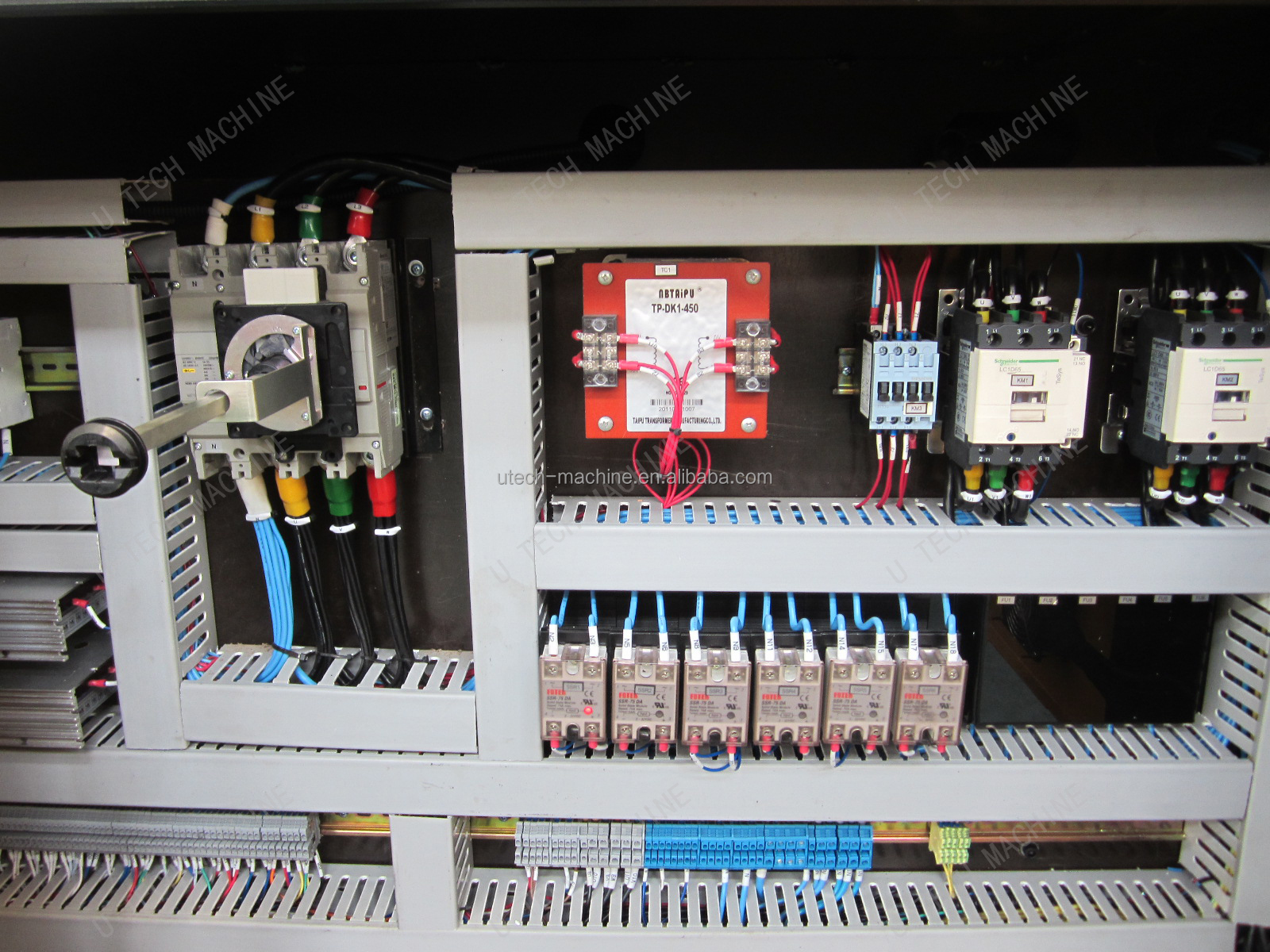

Control System

S/N | Name | Brand | country |

1 | Main motor | ABB | Switzerland |

2 | inverter | MITSUBISHI | Japan |

3 | PLC | OMRON | Japan |

4 | Touch screen | MITSUBISHI | Japan |

5 | Contactor | SCHNEIDER | France |

6 | Thermo- Relay | SCHNEIDER | France |

7 | Air-break Switch | SCHNEIDER | France |

8 | Proximity switch | TURCK | USA |

9 | Photoelectric switch | BANNER | USA |

10 | Air circuit system | SMC | Japan |

11 | Water pump | Southern | China |

Related Products

About U TECH

Certifications

FAQ

Q1:Do you have any reference project? >> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer. Q2:What's your guarantee or the warranty of the quality if we buy your machines? >>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years. Q3: Do you provide customized service? >> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on. Q4:When can I get my machine after I paid? >> A4:We will deliver the machines on time as the date we agreed both side. Q5:How can I install my machine when it arrives? >> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Product Categories : Injection Molding Machine

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)