the first company in designing and producing hot filling gable top carton filling machine in China.

Small automatic Aseptic food Milk gable top Pack Fill Brick carton Box filling Packing machine for apple juice In Zhangjiagang

Product Description

Product Introduction

Product introduction

Gable top carton filling machine is high-tech machinery. The main reasons why users selected our machines are as follows:

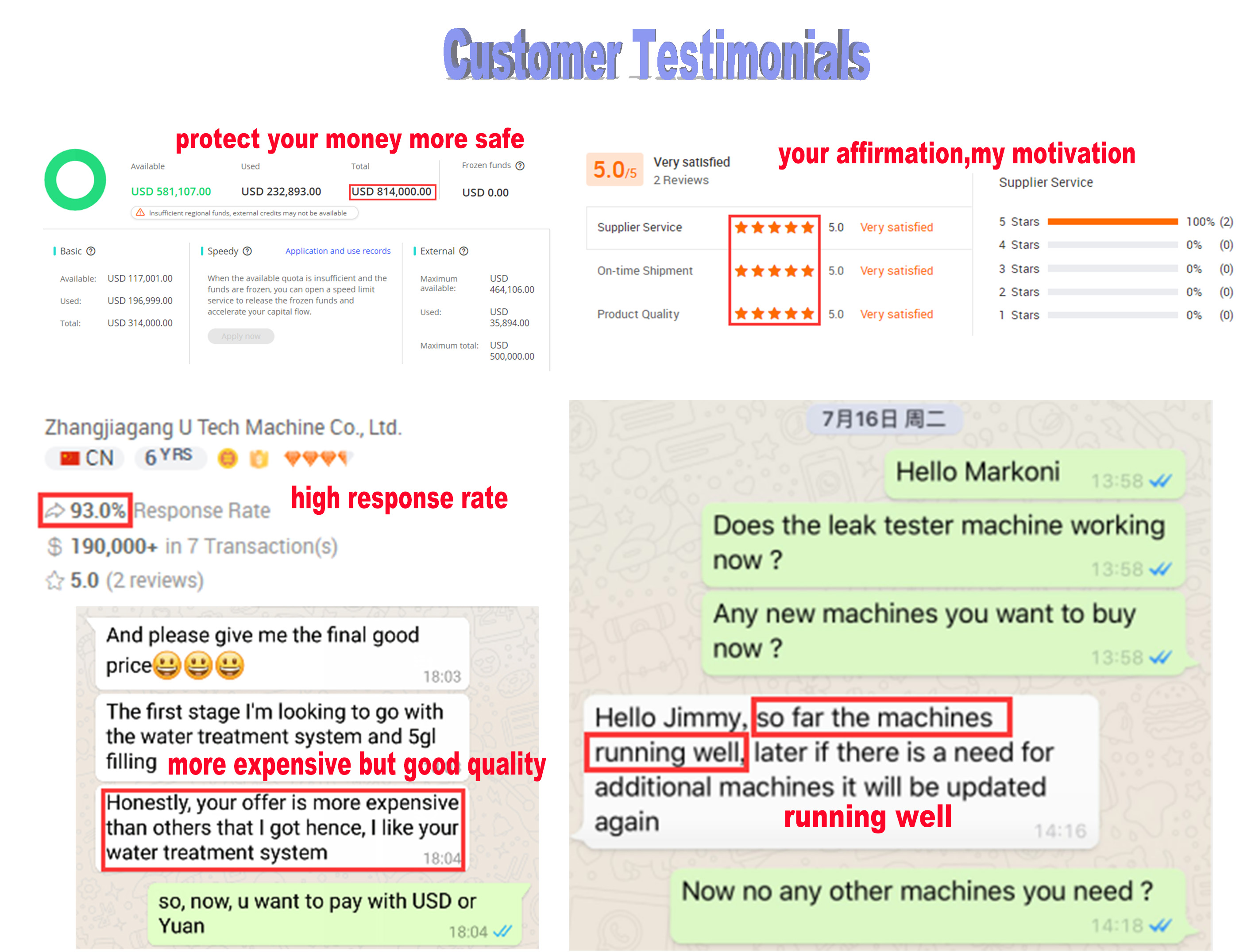

●We have a large quantity of users both in domestic and abroad. The machines are all running well and spoken highly by our customers. The oldest machine we sold has worked for more than 10 years in our user’s factory and is still running well now.

●Our machine applies world top class technique and design principle. All the main spare parts are from international big brand. That ensures the machine’s highly quality and steady performance.

●Our machine’s price is only 1/2 of international brand equipment, while the quality is the same.

●Our company is specialized in manufacturing gable top carton filling machine for more than ten years, and is

the first company in designing and producing hot filling gable top carton filling machine in China.

the first company in designing and producing hot filling gable top carton filling machine in China.

●We provide perfect after-sale service and spare parts in competitive low cost for long term.

●Our machine has got National Standard MC Certification issued by National Weights and Measures Bureau and CE certificate . The quality is reliable.

Technical Parameters

Capacity | 250--1000ml / 1000ml-2000ml (can be filled by onemachine) |

Output | 2000-2500cartons/hour |

Packing material | cardboard carton / aluminium foilcarton |

Carton bottom size | 57*57mm, 70*70mm, 95*95mm, one size for one machine |

Capping | With capping (Optional) cap size: φ26-φ36, one size for one machine |

Shelf life | juice: 1year (normal temperature) |

whipped cream | 12 months (-18℃ storage) |

Filling temperature | 2-50 degree centigrade |

Overall power | 25KW(three phases of electricity) |

Compressed air pressure | 0-1.4Mpa, Flow rate: 1.4-2M3/min, without oil, water and dust |

Cooling water | Flow volume:≥40L/ min Temperature:≤30℃ |

Size | (L*W*H): 3.7m*1.6m*2.8m |

Net Weight | 3500kg |

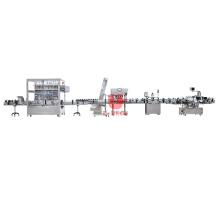

Production line flow

Work flow :

●Carton Forming part: Cardboard -- Put the cardboard onto the mandrel (manually) -- Bottom heating -- Bottom sealing -- Top open carton

●Capping part: Put the cap into the carton's capping hole (manually) -- Ultrasonic welding -- Top Open Carton with Cap (optional)

● Filling part: Put the carton onto the conveyor (manually) -- Top preforming -- Filling -- Top heating -- Top sealing -- Date printing --Finished product. The operation of the filling machine is automatically controlled by computer program, and others are controlled by electric apparatus. The whole progress is controlled by PLC, needs 3 persons to operate.

●Capping part: Put the cap into the carton's capping hole (manually) -- Ultrasonic welding -- Top Open Carton with Cap (optional)

● Filling part: Put the carton onto the conveyor (manually) -- Top preforming -- Filling -- Top heating -- Top sealing -- Date printing --Finished product. The operation of the filling machine is automatically controlled by computer program, and others are controlled by electric apparatus. The whole progress is controlled by PLC, needs 3 persons to operate.

Main Features

1) It is applicable for various specifications.

2) It owns intellectual property rights and many patents rights.

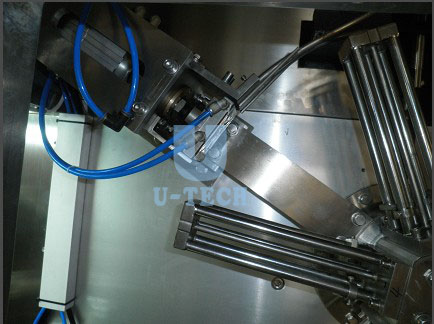

3)The machine is made by closed stainless steel and the move of cartons, top welding and bottom welding are driven by cams.

4)High automatization, Simple process, Easy maintenance.

5)This machine is a dual-purpose machine and it can also apply to paper-AL-PE laminated materials and TTM paper

(plastic-paper-plastic laminated materials).

6)The machine uses HTST(high temperature / transient) sterilization, normal temperature filling to ensure the preservation of content for a long time.

1) It is applicable for various specifications.

2) It owns intellectual property rights and many patents rights.

3)The machine is made by closed stainless steel and the move of cartons, top welding and bottom welding are driven by cams.

4)High automatization, Simple process, Easy maintenance.

5)This machine is a dual-purpose machine and it can also apply to paper-AL-PE laminated materials and TTM paper

(plastic-paper-plastic laminated materials).

6)The machine uses HTST(high temperature / transient) sterilization, normal temperature filling to ensure the preservation of content for a long time.

Details Images

Related Products

Beverage Preparation System

Beverage preparation system is designed by different prescriptions of drinks.Take bottled fruit juice production by concentrated one for example.Before mixing concentrated fruit juice,users should add proper water to pre-dissolve and dilute highly concentrated fruit juice.Then fruit juice is sent to mixing tank where syrup,other auxiliary ingredients and water are added.After that,you can mix fruit juice and customize its volume.Specific technology should be made based on practical conditions and expectations of different products.

High speed emulsification tank

High speed emulsification tank,rotated by the high speed mixer at bottom,speed of mixer is 1440rpm;this equipment is the best one among the similar types in which materials can be mixed well by stirring,extrusion and shearing.

Syrup filter

It applies to the filtration of water and various viscous liquids.It is designed for continuous online filtration to remove impurities on the outer surface of filter screen via highly-efficient mechanical scrapping.

Mixing tank

Mixing tank introduction of foreign advanced technology,has a unique stirred structure,unique features mixed emulsion.It is a set of mixing,emulsifying,homogenizing,dissolution,crushing and other functions in one device.

Double filter

It is suitable for the removal of liquid milk, sugar, beverage, oral liquid, such as invisible solid impurities in the liquid

purification.Two filters are used interchangeably, in the case of non-stop filter replacement, suitable for long-term continuous production.

purification.Two filters are used interchangeably, in the case of non-stop filter replacement, suitable for long-term continuous production.

Amortize tank

The function is to allow the feed to mix well.In the case of material interruption due to external system,play a buffer role.

Homogenizer

It is widely applied in beverage, food, dairy, pharmaceutical, chemical and process industries.It can be with working platform or without. But suggest with platform, is easy for putting the materials into the tank.

Vacuum dearating machine

The deaerator is one of the necessary equipment in fruit juice or fruit tea production line. It is mainly used for deaerating the homogenized juice under vacuum condition and to prevent the juice from being oxidized and then to prolong the storing period of the juice.

Ultra-temperature sterilizer

The system works in aseptic section and normal section,for the technical requirements of filling at low temperature,normal temperature and high temperature.Ultra-high temperature water is used as the media for the heating of materials and temperature adjustment of filling exit,featuring high accuracy.

CIP rinsing machine

1.Auto-flow control for the cleaning solution.2.Automatically regulate the temperature of the cleaning liquid.3.Auto-compensate for the inside tank liquid level.4.Automatically-compensation for the acid and alkali concentration.5.Auto transfer from one

cleaning liquid to another.6.System auto alarm-device.

cleaning liquid to another.6.System auto alarm-device.

About U TECH

Certifications

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready, for testing and teaching your technicians how to run the machines.

Product Categories : linear filling machine

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)