High-Speed Plastic Bottle Cap Compression Moulding Machine

Basic Info

Model No.: ZQ-C24H

Product Description

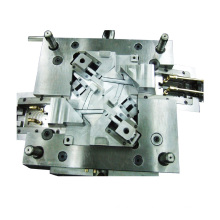

Model NO.: ZQ-C24H Products Output: 15000-18000 PCS/Hr Delivery Date: 30 Days After-Sales Service Provided: Engineers Available to Service Machinery Overseas Specification: Plastic Bottle Cap HS Code: 8477590000 Number of Cavity: 24 Cavities Auto Systems: Fully Automatic Warranty: 12 Months Trademark: ZIQIANG Origin: Taizhou, China High-Speed Plastic Bottle Cap Compression Moulding Machine

ZQ-C24H cap compression Molding Machine is applicable for cap production from thermoforming plastics (PP, PE, etc., ), its rotating design ensures continuous cap production and no injection time, so yield greatly increased.

The machine adopts continuous compression molding hydraulic press for plastic cap manufacturing via the extrusion of dry-blend granulated compounds (i. E. HDPE, PP), metering, pelletting and insertion in the cavities to mould it into the final shape. The capacity of the machine depends heavily on compound properties and the geometry of the manufactured caps.

High-Speed Plastic Bottle Cap Compression Moulding Machine

Equipment Advantages.

1. Intelligent PLC controlling system

2. Human-machine interface, easy & stable operation

3. Machine adopts world-class industry design and processing crafts, exquisite electrical configuration

And superb assembling technology

4. Easy computer operation realizes full-auto production from PP&PE resin to final caps.

5. Rotation compressing cap molding offers shorter recycling time, high yielding and fine final caps,

Caps with no injection point and easy for cap logo printing

6. Cap with high density, short change-over time for one color cap to another.

7. Low energy consumption, output triples compared with the traditional cap Injection Molding Machine

8. Each cap mold is independently compressed, no runner scrap.

9. Easy and low cost mold maintenance

10. High efficiency,low price

High-Speed Plastic Bottle Cap Compression Moulding Machine,equipment information.

Note: The specifications are subject to change without notice for the further improvement.

Note: Custom production accepted. Any client idea tried. Contact us if you need more details on Plastic Bottle Cap Compression Moulding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Bottle Cap Compression Moulding Machine、Plastic Cap Compression Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

ZQ-C24H cap compression Molding Machine is applicable for cap production from thermoforming plastics (PP, PE, etc., ), its rotating design ensures continuous cap production and no injection time, so yield greatly increased.

The machine adopts continuous compression molding hydraulic press for plastic cap manufacturing via the extrusion of dry-blend granulated compounds (i. E. HDPE, PP), metering, pelletting and insertion in the cavities to mould it into the final shape. The capacity of the machine depends heavily on compound properties and the geometry of the manufactured caps.

High-Speed Plastic Bottle Cap Compression Moulding Machine

Equipment Advantages.

1. Intelligent PLC controlling system

2. Human-machine interface, easy & stable operation

3. Machine adopts world-class industry design and processing crafts, exquisite electrical configuration

And superb assembling technology

4. Easy computer operation realizes full-auto production from PP&PE resin to final caps.

5. Rotation compressing cap molding offers shorter recycling time, high yielding and fine final caps,

Caps with no injection point and easy for cap logo printing

6. Cap with high density, short change-over time for one color cap to another.

7. Low energy consumption, output triples compared with the traditional cap Injection Molding Machine

8. Each cap mold is independently compressed, no runner scrap.

9. Easy and low cost mold maintenance

10. High efficiency,low price

High-Speed Plastic Bottle Cap Compression Moulding Machine,equipment information.

| TYPE | MODEL | ZQ-C24H |

| Cap | Number of Cavity | 24cavities |

| Output | 15000-18000pcs/hr | |

| Raw Material | PP/PE | |

| Diameter of Cap | 22-45mm | |

| Height of Cap | 10-25mm | |

| ELECTRICAL SYSTEM | Installation Power | 50kw |

| Actual Power Consumption | 26kw | |

| Power Supply (Three Phase,Five Wire) | 380V 50Hz | |

| AIR SYSTEM | Operatating Pressure | 0.8Mpa |

| Pressure Consuming | 1.0m³/hr | |

| MACHINE | Machine dimension | 3.8x1.8x2.0(m) |

| Machine weight | 3.8ton |

Note: Custom production accepted. Any client idea tried. Contact us if you need more details on Plastic Bottle Cap Compression Moulding Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Bottle Cap Compression Moulding Machine、Plastic Cap Compression Moulding Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Plastic Cap Closure Machine

Premium Related Products

Other Products

Hot Products

Jerrcan Blow Molding MachineFolding Bottle Blow Molding Machine20L Double Station Automatic Blow Molding Machine10L Barrels Making Machine30L Accumulator Blow Molding Machine (TVHS-30L)1L Multilayer Four Station Semi Automatic Blow Moulding Machine with CEHigh-Speed Plastic Cap Compression Moulding MachinePlastic Injection MouldPlastic Preform Injection Moulding Machine (ZQ680-M6)Blow Molding of PET BottlePlastic Preform Mold/Injection MouldAutomatic Bottle Blow Moulding Machine (ZQ-M600-3)Water Bottle Blow Moulding Machine (ZQ-B600-4)small plastic extrusion blow molding machineFully automatic pet bottle blow moulding machine for handled bottlePET Bottle Rotary Stretch Blowing Machine - High Quality (ZQ-R12)